Aircraft Stractural Components

By strengthening the development and production capabilities of composite products, NIPPI provides high-quality products to aircraft around the world.

NIPPI focuses most on the composites design and manufacturing technologies. Being used for about 50% of the major structures of the Boeing 787, the latest passenger aircraft model, composites will play a more and more important role in pursuit of weight reduction/energy efficiency and safety of aircraft in the future. In such a trend of the time, NIPPI is making tireless efforts to offer high-quality aircraft structural components to airline companies all over the world by working hard in research and development, introducing new testing and manufacturing equipment for composites, and further developing strong craftsmanship which we have nurtured over the years.

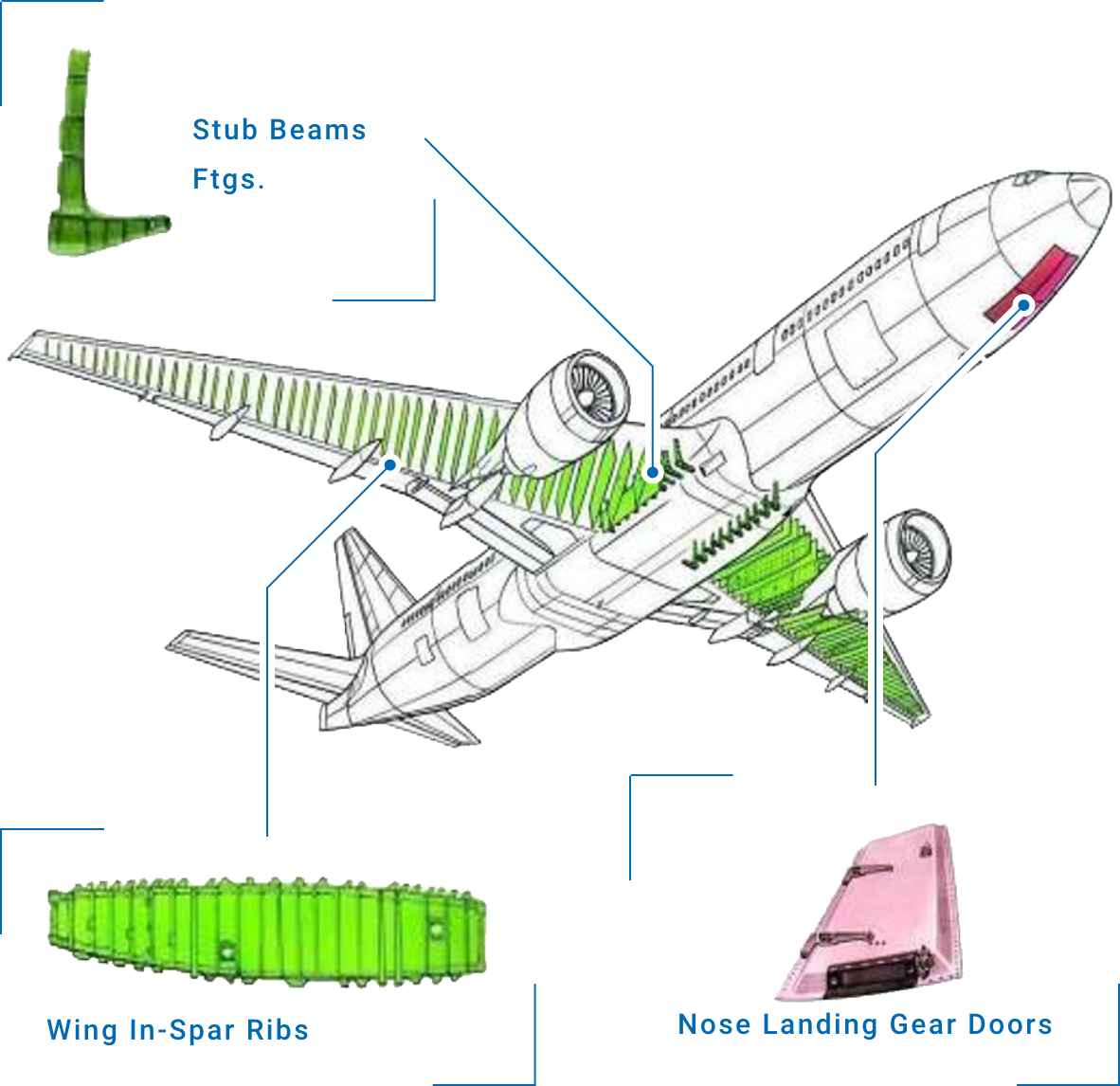

Boeing777

Boeing 747-400/-8

A380

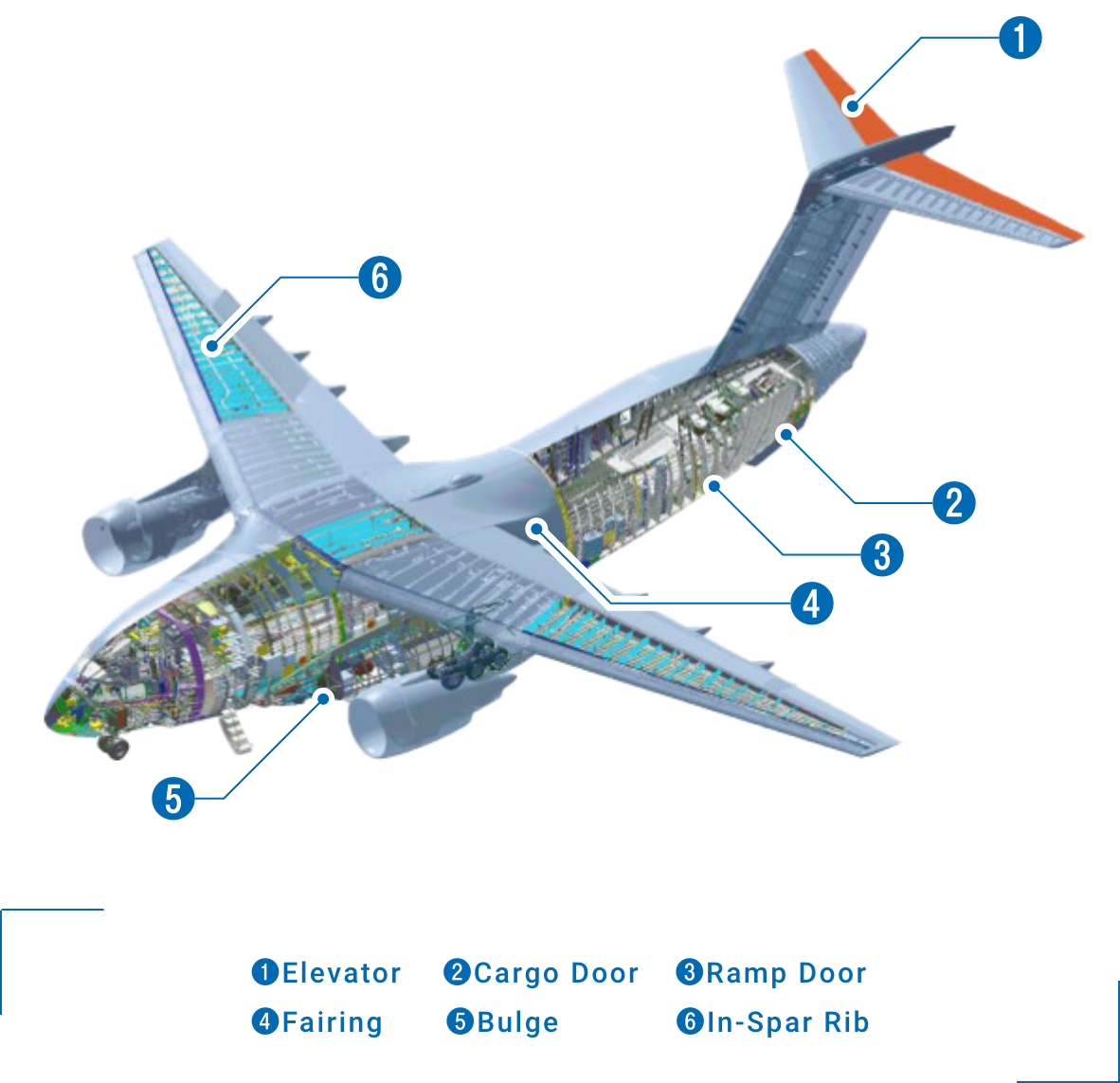

C-2 Transport Aircraft

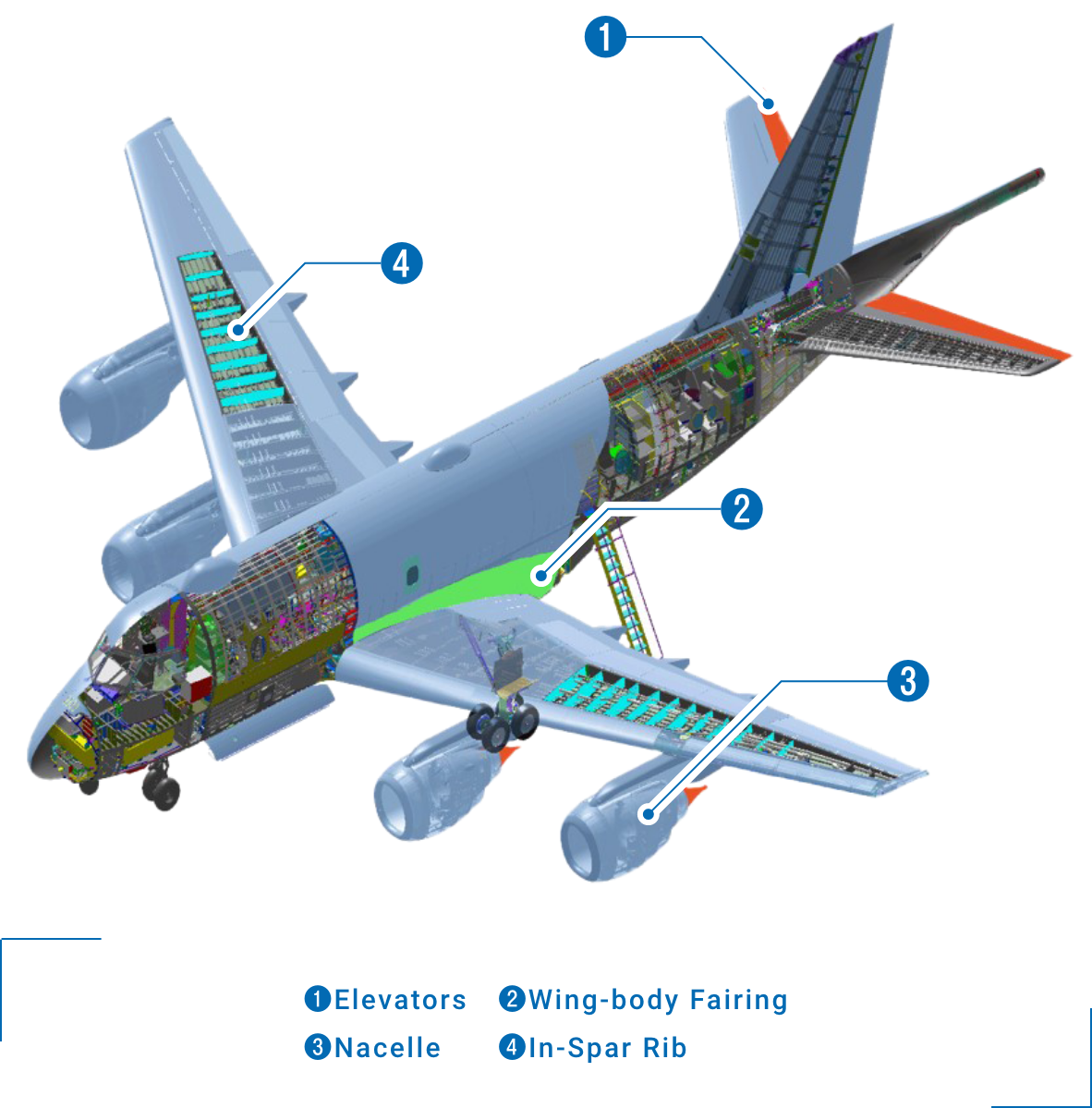

P-1 Maritime Patrol Aircraft

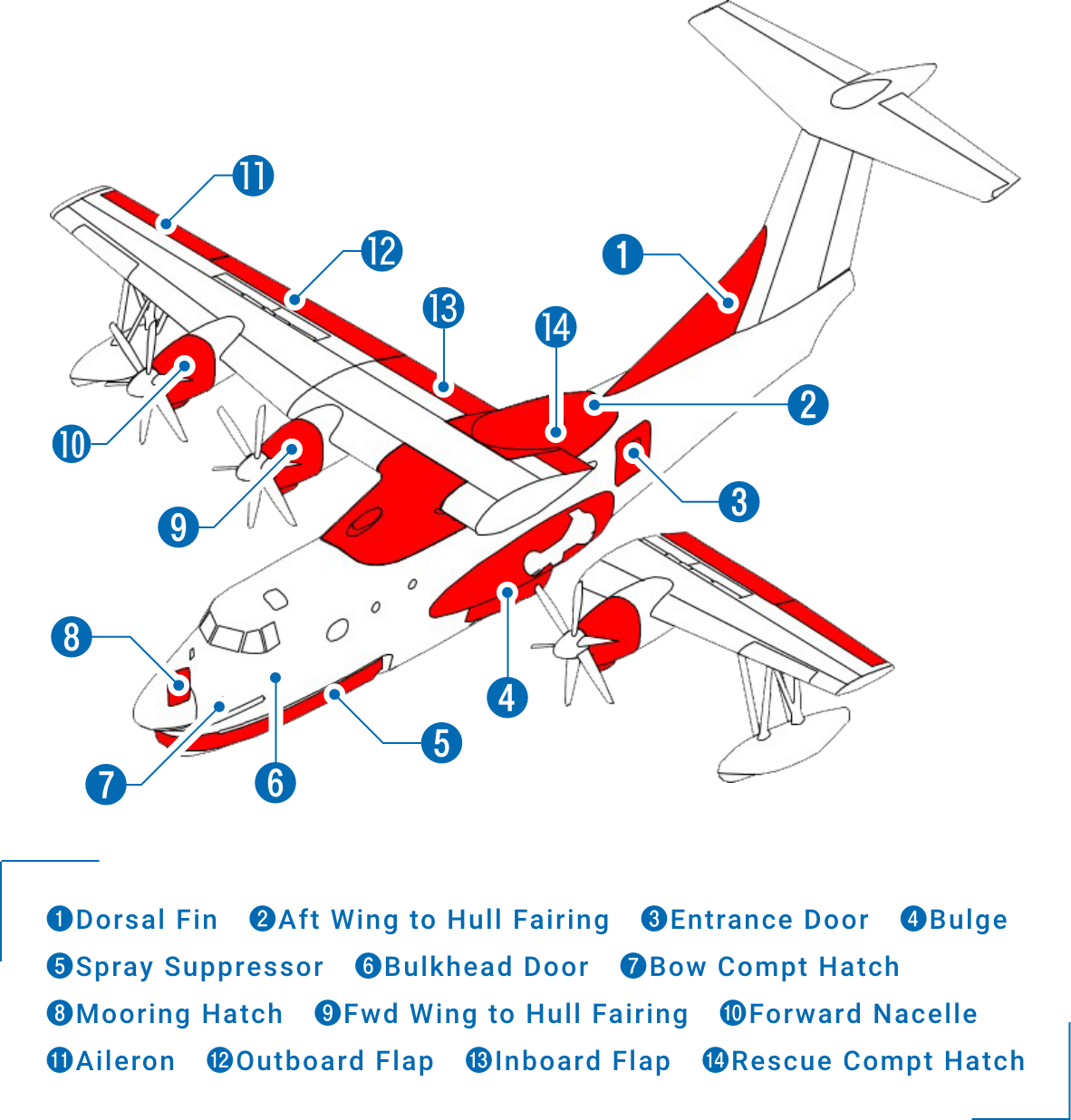

US-2 STOL Search and Rescue Amphibian Aircraft

Aircraft System Products

As an application of aviation technology, NIPPI develops and produces underwing equipment for defense aircraft.

By utilizing know-how in designing and metal working techniques for aviation equipment that we have cultivated over the years, NIPPI develops and produces underwing equipment for fighters, trainers, and helicopters. We have produced pylons and launchers for aircraft such as F-104 Star Fighter, T-2, F-4EJ, F-1, F-15J, T-4, F-2 and OH-1 for the Japan Self Defense Forces so far, and intend to develop and produce equipment compatible with stealth fighters in the future.

-

F-2

-

F-15J

-

Unmanned aerial vehicle

[ application : R&D ]

Space Equipment

-

With unique extension and expansion technologies, NIPPI is expanding the space frontier.

For the structures in space (for example: solar array paddles, antennas and various sensors for satellites), it is essential to be foldable smaller at the time of launch and expandable bigger in space. Employing the composite technology cultivated in the aircraft business, NIPPI developed the "Coilable mast," the first of its kind in Japan, in 1986. Since then, with frontier spirit to challenge unexplored space, NIPPI has worked earnestly to develop the extension and expansion technologies. Meanwhile, we have designed and manufactured extendible masts for the magnetometer of the lunar orbiter "KAGUYA" and almost all extendible masts for Japanese satellites, as well as solar array paddles, separation mechanisms, and antenna expansion systems for many satellites. -

NIPPI is demonstrating its established technology also in the structures for launch vehicles and satellites.

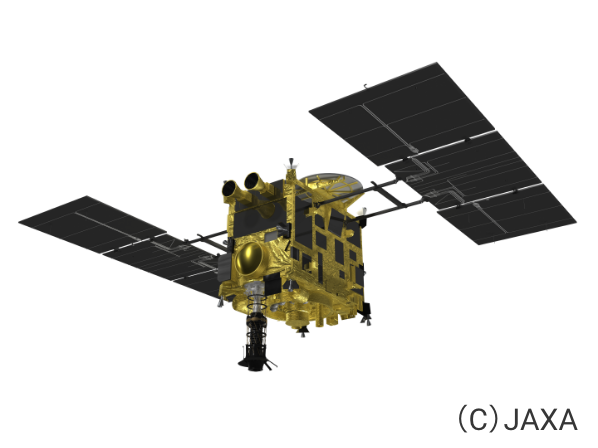

Along with the development of unique extension and expansion mechanisms, NIPPI demonstrates its accumulated aerodynamics technology and high-precision metal processing technology in the fields of design and manufacture of launch vehicle and satellite structures. We have proven track records in designing and manufacturing space structures including the large-scale launch vehicles, H-II A/B, the spring used for the separation of the re-entering capsule from the HAYABUSA asteroid explorer of Japan Aerospace Exploration Agency (JAXA), of which its miraculous return attracted wide interest in June 2010, components of JAXA's H-II Transfer Vehicle (HTV), KOUNOTORI, and many other satellites.

-

HAYABUSA2 robotic spacecraft

-

KOUNOTORI (HTV) automated cargo spacecraft

Industrial Equipment

Nippi developes and manufactures new wind turbine systems with its unique technology.

In 2003, NIPPI applied our advanced aerodynamic, control, and metal processing technologies used for aircraft to the development of a unique wind turbine system that is not affected by wind directions and is highly resistant to harsh environments. One of the system was installed in car carriers in 2004, and another was delivered in 2009 to the National Institute of Polar Research (NiPR) as a prototype of a wind turbine for Antarctica. After completion of the operational testing in Nikaho highland (Akita prefecture) with an environment similar to Antarctica (Showa Station), the same turbine system , which was delivered to NiPR in 2011, is about to be installed to operate at Showa Station. The unique vertical wind turbine system that guarantees consistent performance under the harsh environment of Antarctica attracts global attention currently.

-

Vertical axis wind turbines NWT-10

-

Operation test at Nikaho plateau (Akita pref.) NWT-20